Building a carbon fibre frame on a student budget (eg - next to nothing), was always going to be tricky, especially as carbon fibre is upwards of £21 ($35) per square meter and for a bike frame 2-3 m^2 of material is required. I was able to scrounge about 16 m^2 for a D&T project while in school, so I had enough to spare for this, and probably a few more projects too.

A complete list of the materials I used - all will be explained later;

- Carbon sheet (approx 3m)

- Epoxy resin (about 1Kg) as some goes to waste

- PVC pipe for molding tubes around - clicky

- Mold release wax

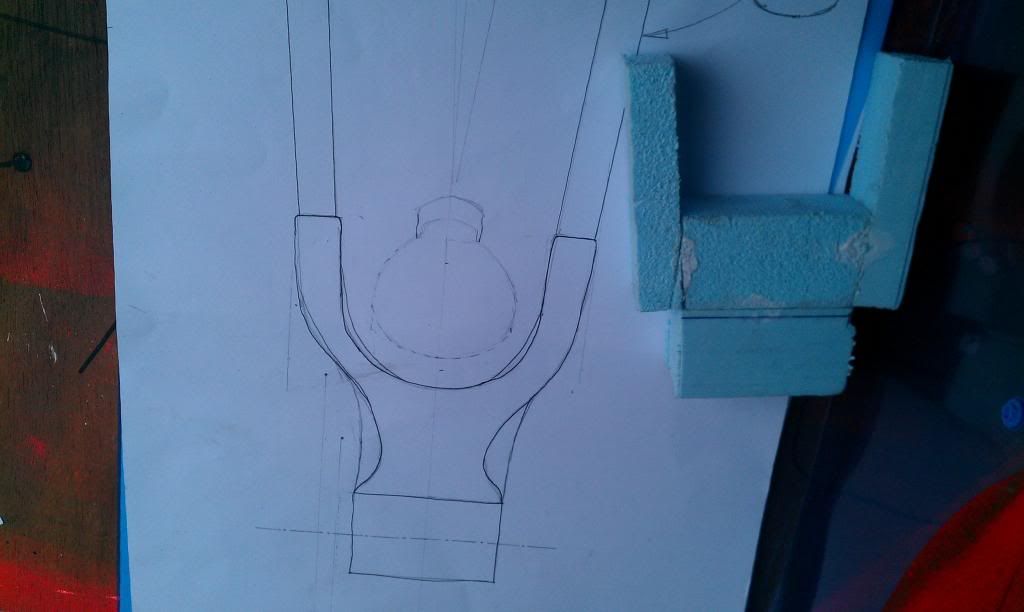

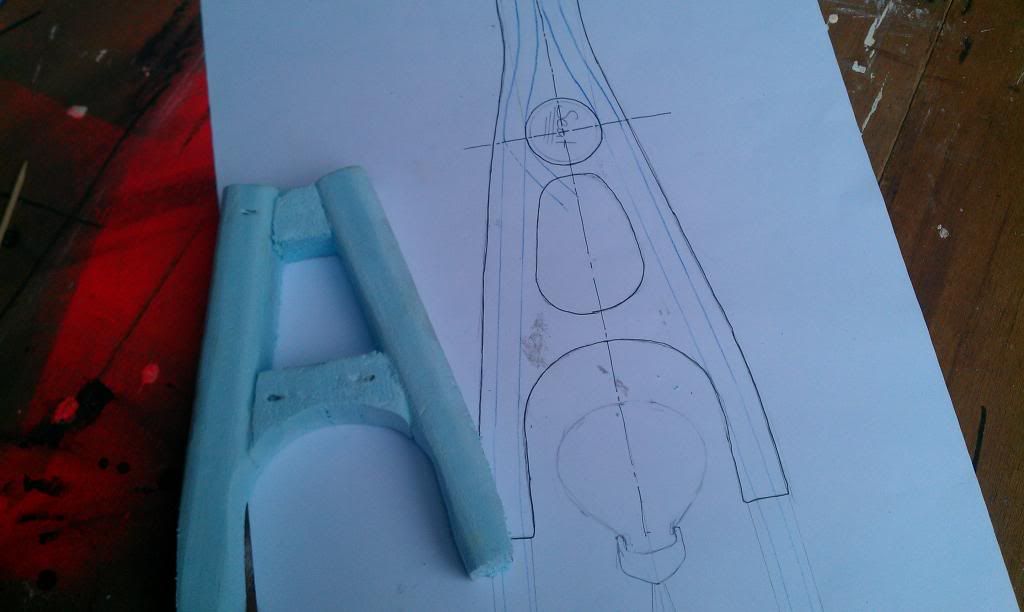

- Blue modeling foam - various sources on eBay

- Rubber tubing to make routing for internal cables

- Glass bubble filler for smoothing curves

Unless linked the easiest and best place to get these is probably easycomposites.co.uk if you're in the UK, and elsewhere google is your friend. Research what is available as there are other methods that may be more appropriate for your project.

As for tools used I have a pretty well equipped garage, but a good supply of gloves, brushes, pots and old rags is useful for lay-up, for shaping and cutting carbon, decent waterproof sandpaper and a sharp hacksaw is advisable.

I opted to use 32 and 40mm plastic pipe to mold the main tubes around, the 32mm would be for the top tube and the 40mm would be for the downtube, I had considered using the 50mm tubing but felt it ma have been a bit too oversized - it hindsight a larger downtube may have been a better idea to help stiffen the frame a bit

For the aluminium inserts for the headtube and bottom bracket I used the parts from the Cadex frame and for the dropouts and some of the rear triangle I decided to use part of the Cadex frame - as my aim for the initial build was to keep it simple and that it was already carbon and roughly the same cross section that I had designed.

|

| An unmodified Giant Cadex rear dropout with an added disc mount - retrobike.co.uk |

This left me with two options for adding a rear disc mount, one would be to do something similar to the above picture, and the other would be to bond a mount onto the seatstay, which is what I decided to do.